-

Channel Cams provide an easy and rugged means to mount a camera at fork level. These cameras fit standard ITA hook type fork carriages. A variety of camera options are possible in this series to give your operator the best possible view. Models are available to fit North American class 2A, 3A & 4A. Some European trucks use the B - standard fork carriage (class 2B, 3B, 4B) which is not compatible.

Channel Cams provide an easy and rugged means to mount a camera at fork level. These cameras fit standard ITA hook type fork carriages. A variety of camera options are possible in this series to give your operator the best possible view. Models are available to fit North American class 2A, 3A & 4A. Some European trucks use the B - standard fork carriage (class 2B, 3B, 4B) which is not compatible. -

The camera assembly shown uses the versatile L3319 Heavy Steel Camera Enclosure with the 30G vibration / 100G shock rated KC2 camera. Typically used on deep reach trucks in freezer applications, the camera is heated and has custom lens installed for proper field of view. Mounted by drilling a mounting hole in the lowest cross member (or stringer) of the inner reach carriage. This camera does not extend with the fork carriage. This camera assembly has been used in other applications as well.

The camera assembly shown uses the versatile L3319 Heavy Steel Camera Enclosure with the 30G vibration / 100G shock rated KC2 camera. Typically used on deep reach trucks in freezer applications, the camera is heated and has custom lens installed for proper field of view. Mounted by drilling a mounting hole in the lowest cross member (or stringer) of the inner reach carriage. This camera does not extend with the fork carriage. This camera assembly has been used in other applications as well. -

The highly adaptable and industry proven VC3 Ball camera is shown here with cushioned magnetic mounts. This camera is nitrogen filled and available in standard 420 TVL or high resolution 700 TVL versions. LIFTek versions of this camera are built with the correct lens and with shock/vibration resistant features for fork lift applications.

The highly adaptable and industry proven VC3 Ball camera is shown here with cushioned magnetic mounts. This camera is nitrogen filled and available in standard 420 TVL or high resolution 700 TVL versions. LIFTek versions of this camera are built with the correct lens and with shock/vibration resistant features for fork lift applications. -

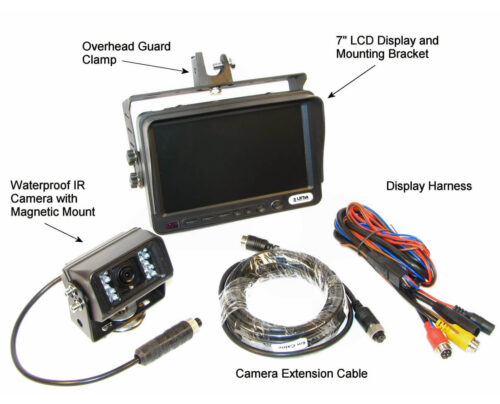

Rear cameras are used much like a rearview mirror except the operator can get a very wide view of the entire area behind the truck in a single glance. Available in a range of lens angles, rear cameras can provide a wide angle view for general safety when backing or with the correct mounting these cameras can also be used for very precise backing in tight quarters, allowing the operator a view into the blind spot directly behind the truck. A magnetic base makes for a quick and secure mounting that can easily be changed if required.

Rear cameras are used much like a rearview mirror except the operator can get a very wide view of the entire area behind the truck in a single glance. Available in a range of lens angles, rear cameras can provide a wide angle view for general safety when backing or with the correct mounting these cameras can also be used for very precise backing in tight quarters, allowing the operator a view into the blind spot directly behind the truck. A magnetic base makes for a quick and secure mounting that can easily be changed if required. -

Mast cameras - these can be mounted anywhere as needed, but are typically mounted on the side of the forklift mast and provide a general overview of the work area in front of the truck. Often used on trucks with poor visibility in front due to special attachments they are a lower cost option to the fork view as the camera does not move up and down with the fork carriage. Super strong magnets allow these cameras to be mounted with no welding or drilling on the mast. Can be moved as needed.

Mast cameras - these can be mounted anywhere as needed, but are typically mounted on the side of the forklift mast and provide a general overview of the work area in front of the truck. Often used on trucks with poor visibility in front due to special attachments they are a lower cost option to the fork view as the camera does not move up and down with the fork carriage. Super strong magnets allow these cameras to be mounted with no welding or drilling on the mast. Can be moved as needed. -

The highly adaptable and industry proven VC3 Ball camera is shown here with cushioned magnetic mounts on the L3520- G1 steel camera guard. This guard can also be welded down for maximum camera protection. This camera is nitrogen filled and available in standard 420 TVL or high resolution 700 TVL versions. LIFTek versions of this camera are built with the correct lens and with shock/vibration resistant features for fork lift applications.

The highly adaptable and industry proven VC3 Ball camera is shown here with cushioned magnetic mounts on the L3520- G1 steel camera guard. This guard can also be welded down for maximum camera protection. This camera is nitrogen filled and available in standard 420 TVL or high resolution 700 TVL versions. LIFTek versions of this camera are built with the correct lens and with shock/vibration resistant features for fork lift applications.